Flexo Press Upgrades

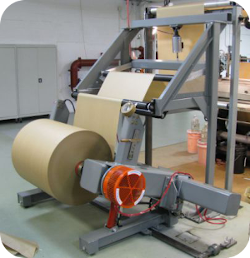

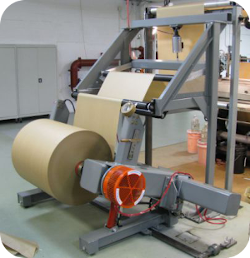

Model EP Junior With Dancer

Greatly increase the amount of product you can produce with your existing press. Shaftless operation speeds the loading and unloading of rolls to get your press back up and making

product. This setup eliminates shaft related costs and injuries. Unwinds are braked and rewinds are fitted with a custom sized motor/ gearbox package. Wound rolls are simply set down onto

the floor, pallet or roll cart. Unwind rolls are lifted directly from the floor.

Staged rolls keep your machinery from being dependant on other equipment for roll changes. If your press speed is the bottleneck and safety is a concern then this system is an excellent

solution

Roll to roll printing is ideal for this setup. This is where the shaftless design can yield the absolute highest production for your press.

Many presses will benefit from utilizing a dancer system on the in-feed. Tension spikes are smoothed allowing you to run higher speeds while maintaining print registration.

Lines requiring slitting prior to rewind may be accommodated in some cases through the use of a special shaft accommodation adapter, a differential rewind shaft and bowed rolls to accomplish

the required separation.

Going shaftless is no longer limited to unwinding. Shaftless rewinding is suitable for many substrates!

Braking/ Motor / Gearbox packages are custom configured. Core chucks vary in style and size depending upon the application.

Load cell or dancer tension control available.

Edge guiding available for unwind and rewind.

Custom loading / unloading configurations available for confined spaces.

|